Main navigation

Acid whey as a valuable raw material for platform chemicals and more

There is not much you can do with acid whey, which is why several million litres of this waste product from the milk processing industry are disposed of every year. This is both costly and not very sustainable. However, there is another way as researchers at the University of Tübingen have shown: acid whey can be used to produce precursors for biofuels, fine chemicals and antimicrobial livestock feed additives. The researchers have set up a pre-start-up company called Wheyfinery in an endeavour to make their scalable biorefinery concept marketable some time in the future.

On average, each individual in Germany consumes over 100 kg of dairy products a year.1 While this sounds healthy and natural, it is not good for the environment: a huge amount of waste – around 13 million tonnes annually – is generated in the form of whey from all the portions of yoghurt, quark or cream cheese we eat.2 If the yellowish, watery milk residue has an almost neutral pH value of 5.5 - 6, it is called sweet whey and can be further processed – for example as protein powder for athletes, pet food, wellness drinks or for use in cosmetics. However, when lactic acid bacteria are involved in producing dairy products, it results in acid whey, which has a pH value of around 4. Acid whey has a lower protein content than sweet whey, making further processing uneconomical. But disposing of acid whey is expensive and energy-intensive.

Environmental biotechnologist Prof. Dr. Largus Angenent considers it a shame to throw away acid whey because – like its sweet counterpart – it contains valuable ingredients that microorganisms metabolise and should therefore be used. Angenent, a Humboldt Professor at the University of Tübingen’s Centre for Applied Geosciences and head of the Environmental Biotechnology working group, began researching the potential of acid whey many years ago in the USA before bringing the idea to Tübingen.

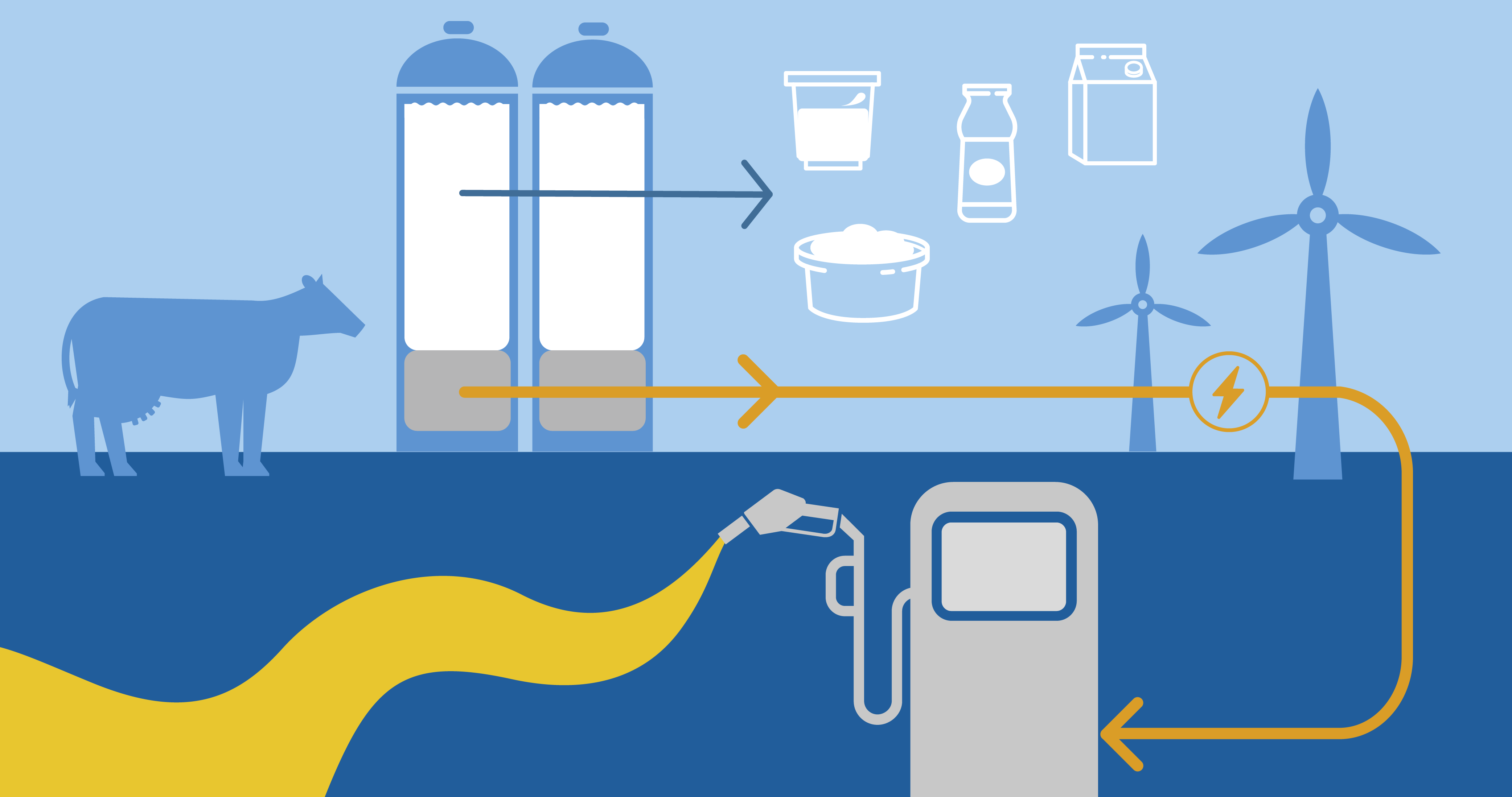

Since 2019, Angenent’s group has been part of the BMBF-funded ‘MolkeKraft’ project which also involves Prof. Dr. Falk Harnisch from the Helmholtz Centre for Environmental Research (UFZ) in Leipzig. The project is focused on producing synthetic fuels and green chemicals from acid whey using a combination of microbiological and electrochemical reactions. This has a positive impact on two levels: on the one hand, the process helps significantly reduce the amount of waste, and on the other, it can help replace fossil raw materials as well as environmentally and socially questional raw materials such as palm oil.

Bacteria produce carboxylic acids from acid whey

"Milk-processing companies are highly interested in finding ways to use acid whey," says Dr. Richard Hegner, a post-doc in Angenent's team who has been involved in the project from the start. "Currently, acid whey is virtually unused for economic reasons, even using it in biogas plants is too uneconomical. So we were motivated by the idea that it would be great to find a way to make something useful from the vast quantities of acid whey." The researchers were successful and now have a temperature-controlled, natural fermentation process for producing biobased carboxylic acids up and running.3 At the heart of the biorefinery is a GMO-free mixture (GMO: genetically modified organisms) of microorganisms that occur naturally in the environment.

It is an open biotechnological system in which the tiny living bioreactors carry out the necessary reactions in two stages without any additional resources – simple but efficient. Lactose is the main microbial substrate and is available in large quantities in acid whey. The first stage of the process involves producing lactic acid as an intermediate product from the acid whey. In the second stage of the process, lactic acid is converted into a mixture of medium-chain fatty acids – carboxylic acids with six to eight carbon atoms – a valuable mix of molecules with oily properties that can be further used in a number of ways.

Replacing fossil raw materials, reducing the quantity of palm oil and antibiotics used

"Interestingly, the carboxylic acids produced from acid whey can be electrochemically refined into a mixture of hydrocarbons that is very similar in composition to paraffin," explains Hegner. "This electrochemical process was developed by our partners at the UFZ4 and can be ingeniously powered by electricity from renewable sources (power-to-fuel approach). In addition, hydrogen is generated as a co-product in this process."

As well as refining acid whey into synthetic fuels, the researchers are also looking into other applications. "The carboxylic acids produced from acid whey can be used to produce fine chemicals for fragrances and flavours in cosmetics, as well as for the food industry," says the environmental biotechnologist. "These acids are currently often extracted from non-sustainable palm kernel oil. Another interesting application of the acid whey-derived carboxylic acids is their use as an additive in livestock feed, as these biologically produced acids have a high nutritional value and an antimicrobial effect. As an admixture to livestock feed, the oily carboxylic acids could therefore play a part in reducing antibiotics in livestock feed."

Pre-start-up Wheyfinery: green platform chemicals for circular value creation and sector coupling

The researchers from Tübingen receive acid whey directly from the production lines of larger companies in the milk processing industry. "We receive regular deliveries of acid whey in 300-litre tanks," Hegner reports. "We then convert it into carboxylic acids in our laboratory, where the process has currently been running continuously and stably on a 2 to 3 litre scale for over 700 days. The carboxylic acids are continuously extracted and either converted into carboxylic acid salts in an electrochemical process by our partners at the UFZ or separated into the respective carboxylic acid fractions via distillation."

The process for producing medium-chain carboxylic acids has been proven to work – so there are many good reasons to recycle acid whey in a bioeconomically sensible way in the future. However, to make sure that the technology doesn’t just remain a small-scale laboratory process at a university, but instead becomes everyday practice in the wider world, the Tübingen scientists decided to set up a company. Wheyfinery is a pre-start-up that has been created in preparation for setting up a company. "Our research-driven spin-off idea is currently in the pipeline. We are looking at sourcing funding through the Federal Ministry for Economic Affairs and Climate Protection’s EXIST funding programme when our BMBF project funding comes to an end later this year."

Wheyfinery is still in its infancy. But the concept has already gained external recognition: as the winner of the Start-up BW Elevator Pitch competition in Tübingen, the business idea has been put forward for the state finals in July 2022. Currently, the Wheyfinery team consists of Angenent, who previously founded a company called Capro-X in the USA, Richard Hegner, PhD student Monika Temovska and some hardworking students who provide further support. "However, since we are all researchers and a company like this also requires other kinds of expertise, the first step is to expand the team with quality control, accounting and business development specialists," he says. "In parallel, we then want to start up the pilot plant with a working volume of 50 to 70 litres – and this is currently under construction." There is potential to expand to other waste material streams in the milk processing industry – but the focus is currently on acid whey.

References

1) Federal Ministry of Food and Agriculture: Versorgungsbilanz Milch und Milcherzeugnisse 2020. www.bmel-statistik.de/ernaehrung-fischerei/versorgungsbilanzen/milch-und-milcherzeugnisse/

2) Research Association of the German Food Industry.: "Nicht-bittere Frischkäse-Produkte aus Mikrofiltrations-Vollkonzentraten – Sauermolkefreies Processing" (2017).

3) Xu, J. et al. (2018): "Temperature-Phased Conversion of Acid Whey Waste Into Medium-Chain Carboxylic Acids via Lactic Acid: No External e-Donor". Joule 2, 280 – 295.

4) Urban, C. et al. (2017): "Production of drop-in fuels from biomass at high selectivity by combined mircrobial and elecrtochemical conversion“. Energy Environ, Sci 10, 2231.