Main navigation

Using proteins extracted from grassland cuttings to produce animal feed and exploit by-product streams

Animal feed often contains protein from soy and importing it causes major environmental harm. In the ProGrün project, researchers at the University of Hohenheim, including a work group led by Prof. Dr. Andrea Kruse, are developing a scalable technological process to extract proteins from grassland cuttings and use them to make sustainable animal feed produced in the region where it will be used. As part of the project, by-products of the process are upgraded to high-quality end products in a biorefinery.

Soy, a protein-rich legume, is used as the basis for animal feed in livestock farming in Germany. However, most soybean meal comes from imports and is not grown domestically. In addition to the well-documented problems in the areas where soy is cultivated – such as rainforest deforestation – the use of soybean animal feed also leads to dangerous dependence on foreign supplies, something that is particularly risky in times of crisis.

In the "ProGrün - Proteins from Grasslands" project funded by the Baden-Württemberg Ministry of Food, Rural Areas and Consumer Protection (MLR), a team of researchers led by Prof. Dr. Andrea Kruse, Head of the Department of Conversion Technologies of Renewable Resources at the University of Hohenheim, has set itself the goal of producing protein-rich animal feed sustainably from regional sources. To achieve this, the researchers are working with research groups led by Prof. Dr. Markus Rodehutscord from the Department of Animal Nutrition and Prof. Dr. Reinhard Kohlus from the Department of Food Process Engineering and Food Powders.

As a local alternative to soybeans, the researchers have focussed on grass and other grassland cuttings that come from the regular mowing of permanent grassland. However, raw grassland cuttings contain lignin and cellulose and are indigestible to non-ruminants such as pigs and chickens. So the proteins in the grass need to be extracted using a technical process and converted to make them digestible. "The idea of extracting and utilising proteins from grassland cuttings is not new at all. It was developed after the war in the 1940s and 50s and resurfaced during the oil crisis in the 1970s and 1980s," explains Kruse's colleague, project coordinator Przemyslaw Maziarka. "However, in neither period did the idea ever become scalable, market-ready technology. The demand for such technology is now very high and we are hoping that this time it will become reality."

Extraction from grassland cuttings to (almost) pure protein

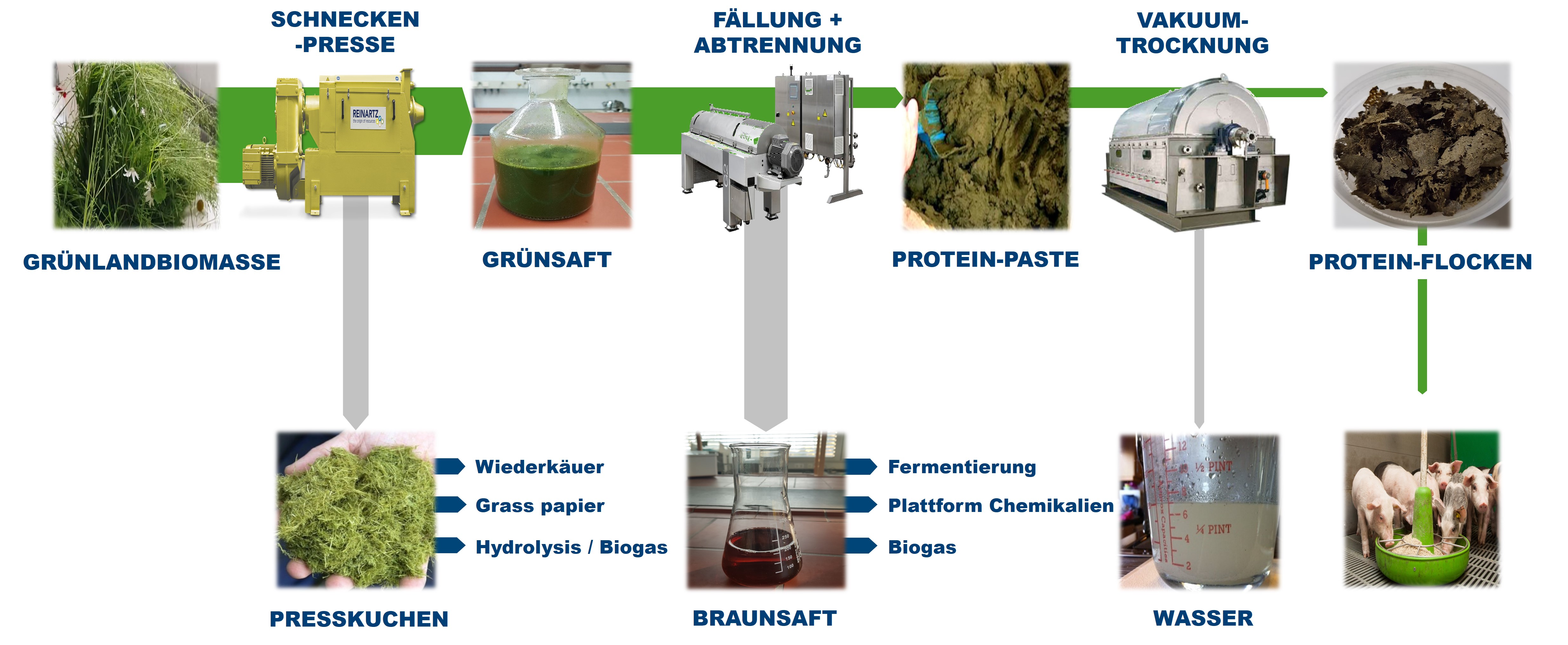

A scalable protein extraction process was developed at the Unterer Lindenhof biorefinery, a University of Hohenheim experimental station near Reutlingen. Maziarka explains: "The process consists of three main steps. Firstly, the grassland cuttings are mechanically processed in a screw press that separates the grass into a solid press cake and liquid press juice. Two thirds of the total quantity of protein remain in the press cake and one third in the press juice. The proteins in the juice are precipitated by adding a small amount of environmentally friendly acid. The suspension of proteins and liquid is then separated in a centrifuge. The solid protein paste is subsequently dried in a vacuum dryer to remove any residual moisture and the completely dry protein flakes are ready for long-term storage and to be added to animal feed."

The researchers analysed the composition of the grass protein feed and compared it to the soybean-based variant. "In terms of dry matter, the grass protein feed has a slightly lower total protein content than the soybean meal. However, the amino acid patterns1) are very similar, which indicates that the grass protein feed is of a similar quality to the soybean meal," explains Maziarka. The first feeding trials with chickens and pigs have also been promising: "The trials showed that our grass protein can partially replace soybean meal as a feed component. However, the exact extent of this still needs to be investigated."

The taste of the grass protein is still the greatest challenge: "The grass protein feed has a very bitter flavour. This is down to the fact that the protein flakes contain precipitated secondary metabolites2) in addition to the isolated proteins," says the expert. In a future project, the researchers are planning to isolate a pure protein mass – without odour or taste – which can then also be used for human nutrition, for example as an additive in yoghurt. "Our current grass protein feed has a protein content of 30 to 40 percent; the isolated protein powder can contain up to 70 percent or more," says Maziarka.

On-farm approach with zero waste

During extraction, which takes place in the biorefinery plant on the farm (on-farm), two by-product streams are produced that the research team would like to utilise further as part of a bioeconomy: firstly, the lignocellulose-containing press cake that is produced during pressing. This contains two thirds of the original amount of protein and can potentially be fed to ruminants such as cattle. "The press cake might even be best suited as feed in the form of silage or dried pellets rather than raw grass, as animals that eat raw grass often ingest too much protein," say Kruse and Maziarka.

"In addition, the fibres in the press cake can be used to produce grass paper. We are in contact with a company that has the relevant expertise. Fungi can also be cultivated on the press cake: as the fungal mycelium grows, it binds together the fibres in the press cake and can be processed into insulation foam, for example," says Kruse, pointing to other possible uses. "And finally, the press cake can be used as a substrate for the biogas plant at the Unterer Lindenhof experimental station. The fermentation residues can then be used to fertilise surrounding farmland, thus closing the nitrogen cycle."

Full of juice - producing platform chemicals using green chemistry

The second by-product stream is the brown juice that remains after the precipitated proteins have been separated from the press juice. This juice contains a large amount of simple sugars that can be used as a starting material for fermentation, biogas synthesis or for producing platform chemicals.

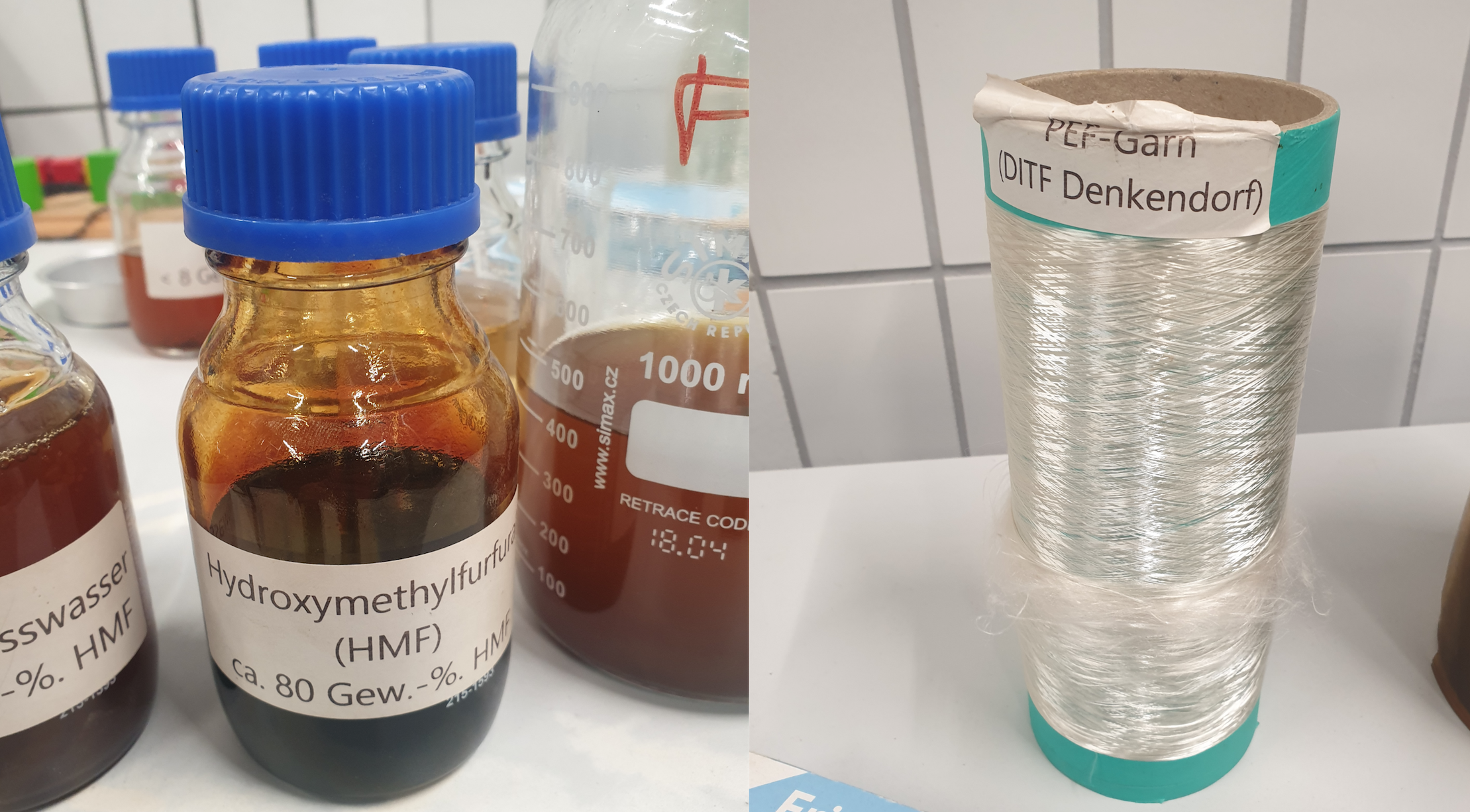

The researchers are focussing primarily on the synthesis of the platform chemical HMF-5 (5-(hydroxymethyl)furfural), from which bioplastics (polyethylene furanoate, PEF) can be produced. "A special feature of this on-farm approach is that the platform chemicals are synthesised with the help of green chemistry. We thus avoid the use of toxic substances but have to accept a lower yield," says Kruse. This is not only safer for the plant's employees but also opens up further options for use. Kruse explains: "Physiologically, HMF-5 increases oxygen uptake from the blood into the body cells in domestic animals and humans. This means that HMF-5 has the potential to be used as a dietary supplement and as a drug for people with sickle cell anaemia."

Many paths to market if we work together

In order to make the process scalable, the team is working with various agricultural partners including grassland cuttings producers and processors. "For the technology transfer to succeed, we need a research consortium with several partners," Kruse and her colleague tell us. Maziarka points to the potential of the biorefinery: "Thanks to the many recycling options for material flows, we have numerous possibilities for developing the biorefinery further and making it market-ready: the path to success might be via platform chemicals as a product or perhaps something else." Kruse adds: "In terms of strategy, it makes sense to first have a small market with high prices and then a large market with low prices, such as animal feed as a product. The more production plants there are, the lower the price."

Overall, the researchers are optimistic about the future and hope to develop further partnerships with agricultural partners from Baden-Württemberg to set up as many on-farm biorefineries as possible in the years to come.

Infobox: ProGrün - Proteins from Grasslands

Project duration: 1st December 2020 to 30th November 2023

Research groups involved at the University of Hohenheim:

· Prof. Dr. Andrea Kruse, Department of Conversion Technologies of Renewable Resources

· Prof. Dr. Markus Rodehutscord, Department of Animal Nutrition

· Prof. Dr. Reinhard Kohlus, Department of Food Process Engineering and Food Powders

Funded by the Baden-Württemberg Ministry of Food, Rural Areas and Consumer Protection (MLR)

Footnotes:

1) Measure indicating the amino acid composition of proteins.

2) Secondary metabolites are a group of chemical substances that are not necessarily vital for plants. They are used as a defence against herbivores, for example.