Main navigation

Chitin for the development of sustainable materials for use in the construction and other industries

Pliable and robust, light and stable - it sounds like an ideal material for the construction and many other industries. A team of researchers at the University of Stuttgart is researching what purposes the naturally good properties of chitin can serve.

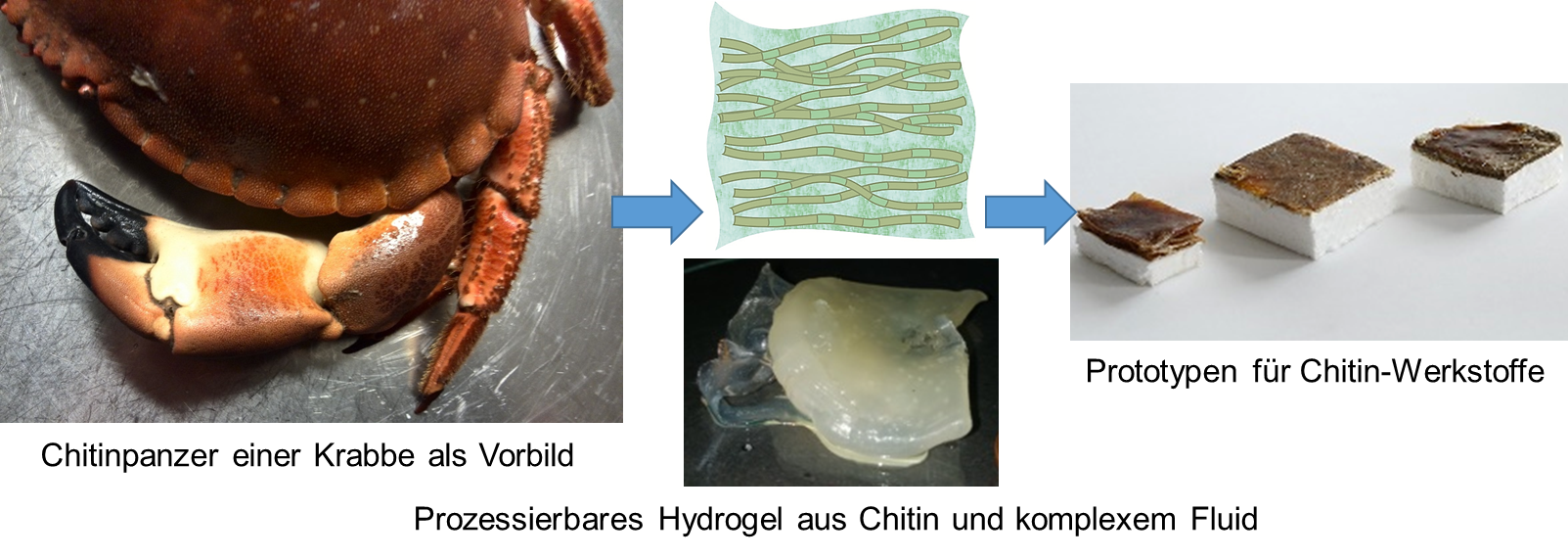

It all began with the Stuttgart team of researchers carrying out a general search for biological, renewable and sustainable raw materials that quickly became focused on chitin, the second most abundant biopolymer on earth after cellulose. "Chitin is extremely versatile and is, for example, a component of lobster shells, which are hard to crack. It is also a structural molecule in something as delicate as an insect wing or in the soft shell of mealworms, and chitin is also found in fungi and diatoms," says Prof. Dr. Sabine Laschat, Professor of Organic Chemistry at the University of Stuttgart. With a research team from six University of Stuttgart institutes covering disciplines ranging from the natural sciences to building materials science and sustainable construction systems, Laschat is seeking to use chitin to create the basis for novel and sustainable materials for application in the construction and other industries.

Chitinfluid - chitin as a resource for multifunctional materials via water-based complex fluids

The Chitinfluid project has also convinced the Carl Zeiss Foundation. Starting in January 2021, the Foundation will fund the project with up to two million euros for a period of four years as part of its "Perspectives" funding line. One of the biggest challenges lies right at the beginning of the project: the researchers have to find a way to transform chitin into a form that can be processed as a fluid. "We cannot melt chitin thermally, as this would destroy the polysaccharide. If we were to crush chitin we would get granules, which cannot be modified as required,” explains Laschat. It really isn’t an easy material for the researchers to work with: "What we are dealing with is polymer chains connected to each other via extremely strong hydrogen bonds. Chitin also forms a superstructure consisting of fibrils and helices." The research group would like to penetrate the secret of chitin and find out how its hierarchical structure can be broken down and formed.

Laschat’s team is therefore initially going back to basic research to study how this is done in nature. Diatoms are a suitable model organism for this purpose. These single-celled algae produce chitin filaments that connect them to one another. "Diatoms can be cultivated in seawater relatively easily, allowing us to use them as an object of investigation. We want to obtain structural information - from less than a nanometre to the submillimetre range - using, among other things, high-performance electron microscopy and an extremely powerful X-ray scattering system that will be purchased with project funds. We will be using chemical experiments to gain an understanding of chitin biosynthesis and how this process can be influenced," says Laschat. Of course, Laschat and her colleagues already have a fair few clues. Research over the next few years will show whether they are right. One important lead that is being pursued is the use of ionic solvents and the transfer of the dissolved chitin into hydrogels.

Thanks to chitin: lightweight concrete of the sustainable kind

Chitin-containing hydrogels are a very exciting form of water-based complex fluids, because they have the potential to be processed into materials with very different, controllable properties. And this is precisely what makes them so interesting for the construction sector. The research team is seeking to combine them with concrete, among other things. Both layer and pore systems, in which concrete pores, for example, are filled with chitin-based foams, are being envisaged. "In conventional composite building materials, concrete is often combined with polymer foams. However, these are difficult to recycle, and pollute the environment. Our chitin-based fluids and the foams produced from them need to offer the same material advantages as conventional building materials, but we also want them to be easily degradable using natural microbial enzymes," says Laschat. As part of the project, the team wants to produce and test prototypes of special composites consisting of chitin foam and concrete as well as monolithic, mineralised foams based on mineral binders and chitin from the kilo to the ton scale. Potential applications include thermal insulation and acoustic absorption. Chitin-based materials could also reveal their strengths in other areas. Since they are not only light and robust, but also hydrophobic, i.e. water-repellent, they could be used in the outer shell of buildings and also of vehicles. The team of researchers also believes that chitin-based hybrid materials could conceivably be used as photonic materials for replacing effect pigments.

As the manufacture, application and disposal of conventional composite building materials are becoming increasingly complex and thus more expensive due to the environmental problems they cause, sustainable solutions are becoming more and more economical. Investigating the bioeconomic benefits of the chitin-based new materials more closely is definitely on the Stuttgart group's agenda in the medium term. "Even if we were only able to achieve minimal changes towards more sustainability in the building sector with chitin-based materials, overall, these changes can make a big impact," says Laschat, especially, as she explains, because the construction sector is responsible for 40 percent of global energy consumption, 35 percent of global CO2 emissions and 45 percent of global resource consumption.