Main navigation

Swabian lavender cultivation: aesthetic and sustainable

Blue-violet, fragrant fields like those in Provence may soon become a common sight in the Swabian Alb. As part of the AlbLavendel project, the University of Hohenheim along with a company called naturamus GmbH and the German Institutes of Textile and Fibre Research Denkendorf has started to investigate the cultivation of lavender, the production of essential oils and the use of distillation residues for producing textile fibres in the local region.

As a result of industrial production techniques, increasing specialisation and global marketing, regional value chains have become less important. However, in recent years, there has been a shift in thinking, as short transport routes and local processing of raw materials not only reduce the environmental footprint but can also create jobs and strengthen rural areas. It also makes the supply chain more transparent and reduces the impact of global events.

"We like to produce our raw materials ourselves, as this allows us to carry out good quality control," explains nutritionist and agronomist Maria Tippmann from naturamus GmbH in the city of Aichelberg. The company is a subsidiary of WALA Heilmittel GmbH, which purchases almost 1,000 raw materials for producing natural cosmetics and anthroposophic medicines, but also produces its own fatty oils, i.e. liquid fats (triglycerides), in its oil factory by pressing stored seeds and nuts. The company also further processes essential oils, among other things, in its distillation and analytics department. These mixtures of substances extracted from flowers, leaves or fruits are somewhat volatile and are produced directly after harvesting in the country of cultivation.

Regional lavender cultivation put to the test

True lavender, Lavandula angustifolia, the 2020 medicinal plant of the year, has been used for centuries as a remedy to soothe and reduce stress, insomnia and anxiety.1) In ancient Rome and Greece, lavender, whose name is derived from the Latin verb lavare meaning to wash, was also used as a fragrance and bath additive (although Spanish lavender was preferred at the time). The aromatic, small bush originates from the coastal regions of the Mediterranean and needs plenty of sun, but only nutrient-poor soil. Provence is a well-known large cultivation area, but Bulgaria has also become one of the main producers of lavender oil.

The idea of cultivating the plant in the Swabian Alb and producing the popular and frequently used essential oil locally originated at WALA 20 years ago. As part of a planned bioeconomy cooperation between Ralf Kunert, Managing Director of naturamus, Dr. Sabine Zikeli from the Centre for Organic Agriculture at the University of Hohenheim and PD Dr. Thomas Stegmaier from the German Institutes of Textile and Fibre Research Denkendorf (DITF), the idea was revived and expanded to include fibre production. This is because the AlbLavendel project, which was funded by the Baden-Württemberg Ministry of Food, Rural Affairs and Consumer Protection (MLR) from August 2021 to late 2022 as part of the state's strategy for a sustainable bioeconomy, aims to make full use of the plant.

In the first step, the partners selected three French and two Bulgarian varieties of true lavender. The selected sites in Hülben near Reutlingen, Bichishausen near Münsingen and Bad Boll in the Göppingen district represent different growing conditions in the Swabian Alb. "Unfortunately, the cuttings arrived very late, so we couldn't plant them until late November 2021," says Carolin Weiler, the Hohenheim scientist in charge of cultivation. Fortunately, as the plants were already in winter dormancy, the night frosts that set in shortly afterwards didn't do them much harm. In contrast, the only French variety grown from seed froze completely and had to be replanted the following summer. In Hülben, however, it was too wet in November, so the plants were stored and not planted in the fields until spring 2022. Weiler explains: "In retrospect, this turned out to be a stroke of luck; this site is currently the best location. Ideally, planting should take place in spring or September to give the bushes time to establish."

For planting, the scientist used machines available on farms that are actually designed for planting leeks. This meant that the roots and leaves needed to be shortened prior to planting, which involved a lot of additional manual labour. The individual varieties were each cultivated in three strips at least 90 m long in three replicates, resulting in a trial area of 0.6 to 0.7 ha at each location.

First conclusions on growth behaviour already possible

Already in the first year, clear differences became apparent, both between the lavender varieties and the growing areas. In Bad Boll at an altitude of just over 400 m above NHN (standard elevation zero), all the plants developed one to two weeks faster than at the other two sites, which sit at an altitude of about 700 m above NHN. The Bulgarian varieties flowered everywhere about two weeks earlier than the French ones and overall thrived better than the latter. Since the plants should be as vigorous and bushy as possible for a good oil yield, most were cut back before flowering and only a few specimens left for the growth analyses.

"We cannot say much about the quality of the oils yet," Tippmann explains. "At the moment [July 2023], the first harvests are taking place in Bad Boll. The yield is about two percent, which is in a similar range to other lavender oil producers.This means we get about 200 g of oil from 10 kg of plant material." Preferably, only the flowers are harvested, ideally in dry weather in the afternoon. However, as lavender bushes also produce lateral, lower shoots, it is not easy to adjust the harvesting machine, and the cuttings always contain a certain amount of stalks.

The essential oil is then extracted by steam distillation. Tippmann adds: "To be able to compare the oils with each other, we harvest and process the plants of the same variety from each location. However, the sensory properties can only be evaluated after a few weeks, because the components are still reacting with each other or evaporating."

Each variety has its own aroma, but the weeds harvested along with it can have an influence. "Especially in the first few years, until the rows are closed, growing lavender requires a lot of manual labour, you have to hoe weeds extensively," says Weiler. Fortunately, if the plants remain pest-free, they can stay in the field for up to 20 to 25 years, so the effort is worthwhile.

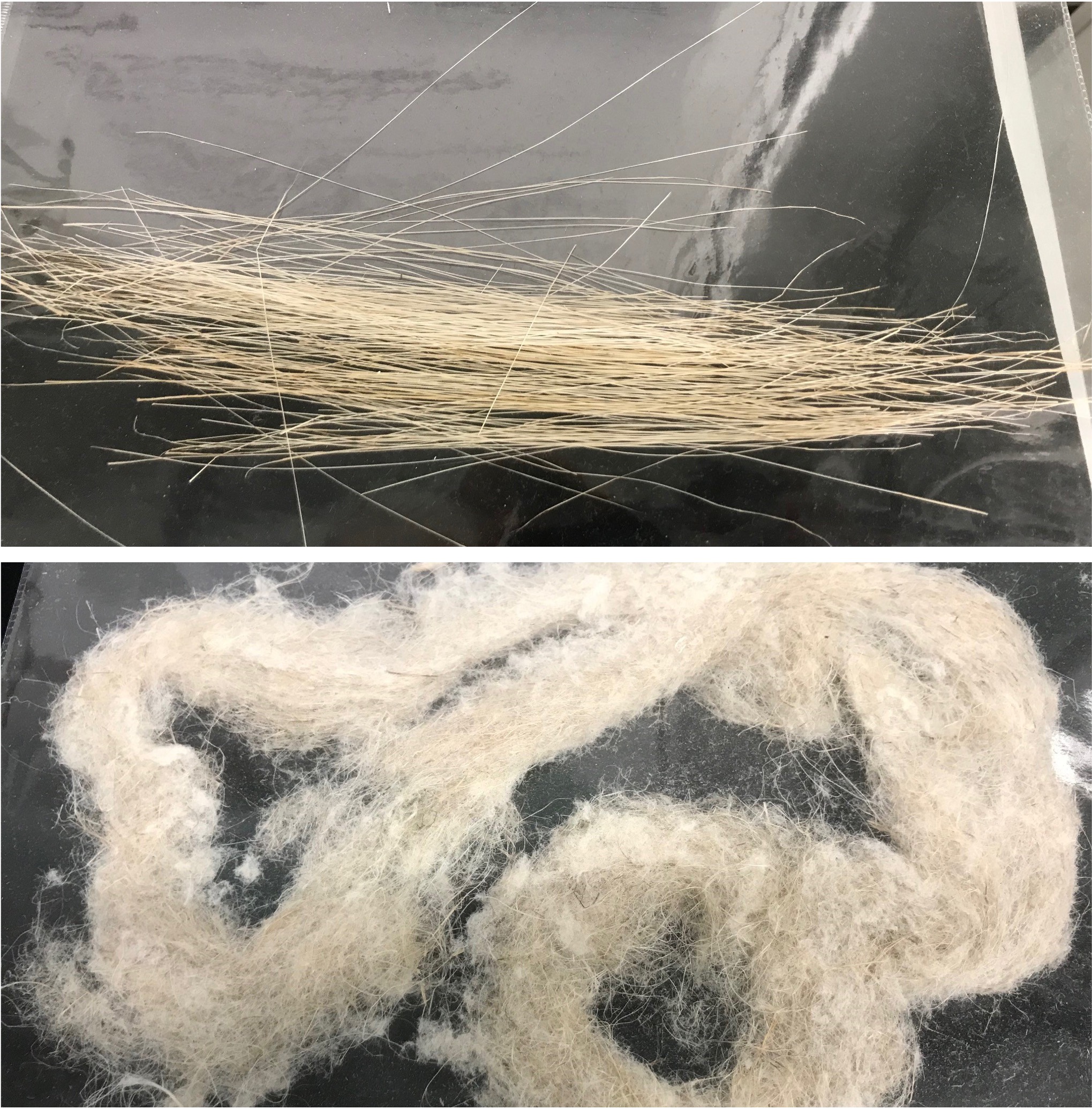

Basic work on fibre extraction completed

In addition to producing essential oils, the AlbLavendel project also aims to utilise the distillation residues. "Last year, we worked out how to obtain fibres," says Stegmeier. This was quite a challenge, as relatively fine fibres are needed for textile production to ensure skin compatibility. In addition, the lavender plant is an exception because the fibres are located under, rather than in, the bark in the "corners" of the plant stalk. The engineer and his team have so far used material from France for their investigations. "Separating the elementary fibre from the lignin scaffold [woody plant parts, editor's note] was the crucial task. We managed to do this with the help of enzymes, and were eventually able to spin yarn suitable for clothing." The fibre yield from the distillation residues is between five and ten percent.

But there are still many questions to be answered. Since only the stalks are needed for fibre production, it might make sense to separate them from the flowers before distillation. However, whether the fibre is just as good or better from fresh plants is something that still needs to be investigated.

Further funding is needed

At the moment, however, the work at the DITF is on hold because funding has run out and time and resources are in short supply. The University of Hohenheim has also had to scale back its activities for the same reasons. Nevertheless, everyone involved is still very interested in AlbLavendel and hopes that further financial support will soon be forthcoming so that the vision of natural cosmetics made from regional ingredients combined with sustainable textiles can become a reality. However, it is already apparent that the visually appealing lavender fields are attracting a lot of interest from the public.

Literature:

1) Echter Lavendel: Arzneipflanze des Jahres 2020. Pharmazeutische Zeitung. https://www.pharmazeutische-zeitung.de/arzneipflanze-des-jahres-2020-114013/