Main navigation

Working towards a hydrogen economy with a wastewater biorefinery: the SmartBioH2-BW project

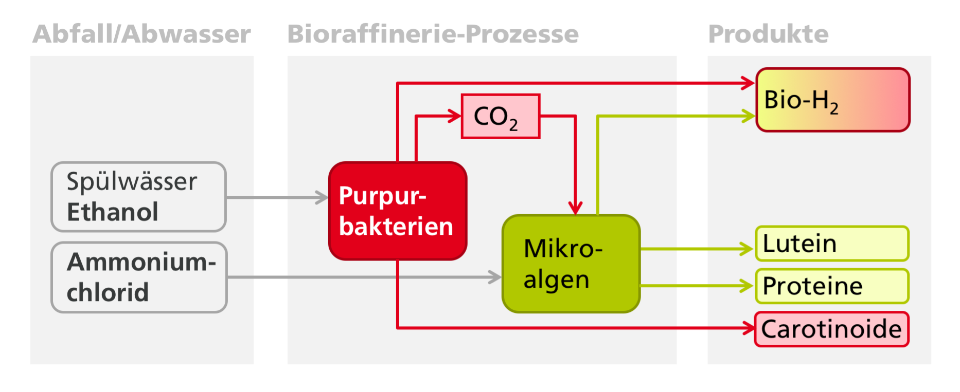

A biorefinery that uses industrial wastewater and residual material streams is being built in Rheinfelden (Baden). It will have two interlinking bioreactors, one with purple bacteria and one with microalgae, and will synthesize biohydrogen as well as organic basic materials such as carotenoids and proteins. SmartBioH2-BW is a pilot project run by the Urban and Industrial Biorefineries initiative and funded by the Baden-Württemberg Ministry of the Environment, Climate Protection and Energy Sector with European Regional Development Fund (ERDF) funds.

If we are to succeed in limiting man-made global warming to 1.5 °C by the end of the century in accordance with the Paris Agreement, the economy based on fossil carbon sources must be sustainably transformed and the balance of global greenhouse gas emissions - above all carbon dioxide (CO2) - reduced to zero. For this fundamental transformation of the global economy, hydrogen (H2) - along with renewable energy for power generation - is considered the energy source of the future. As the European Commission stated, "hydrogen is the missing part in the puzzle to a fully decarbonized economy." To this end, the German government unveiled its National Hydrogen Strategy in June 2020, which is providing billions of euros in funding to get the sustainable hydrogen economy of the future off the ground.

Industry has long used H2 as a versatile feedstock and clean energy source (requiring only oxygen and producing water when energy is released), for example in the synthesis of ammonia used for fertilizers, methanol production, steel production and oil refining. The crux is that the most economical and widely used H2 production process is based on natural gas (methane), generating eleven tonnes of CO2 per tonne of H2, which must either be emitted into the atmosphere or captured and stored in a complex and expensive manner (carbon capture and storage, CCS). H2 gas is invisible, which is why specific colour codes based on how the hydrogen is sourced are used; hydrogen produced from natural gas is referred to as "grey hydrogen".1)

To achieve the climate targets, it is crucial that the balance in hydrogen production, storage and use is CO2-neutral. This is known as ‘green hydrogen’ (biohydrogen), which is obtained, for example, when the energy for the electrolytic splitting of water into hydrogen and oxygen is supplied by the wind or the sun. So far, these processes are still relatively inefficient and expensive. The fact that microorganisms are able to produce hydrogen was described by Felix Hoppe-Seyler, one of the pioneers of molecular biology, back in the late 19th century. Since then, it has been shown that numerous bacteria, fungi and even green algae can produce biohydrogen. Different metabolic pathways are used to produce hydrogen, and have recently attracted major research interest as they may open up an alternative, climate-neutral and cost-effective way to produce ‘green hydrogen’ as an energy source of the future.

Coupling of the synthesis capacities of bacteria and algae

The SmartBioH2-BW project coordinated by the Fraunhofer Institute for Interfacial Engineering and Process Engineering IGB is pursuing a promising approach for the production of biohydrogen to contribute to Germany’s energy transition and future hydrogen economy. The focus is on a bioreactor with purple bacteria that can produce biohydrogen from organic material. The project uses Rhodospirillum rubrum, a so-called photoheterotrophic non-sulphur purple bacterium that can produce hydrogen gas in the presence of light and absence of oxygen from a variety of substances, such as those found in waste and wastewater. The photosynthetic apparatus of these purple bacteria (which differs substantially from that of green plants) contains carotenoids, which can be extracted from the bacteria as a sought-after by-product for the cosmetics and food industries.

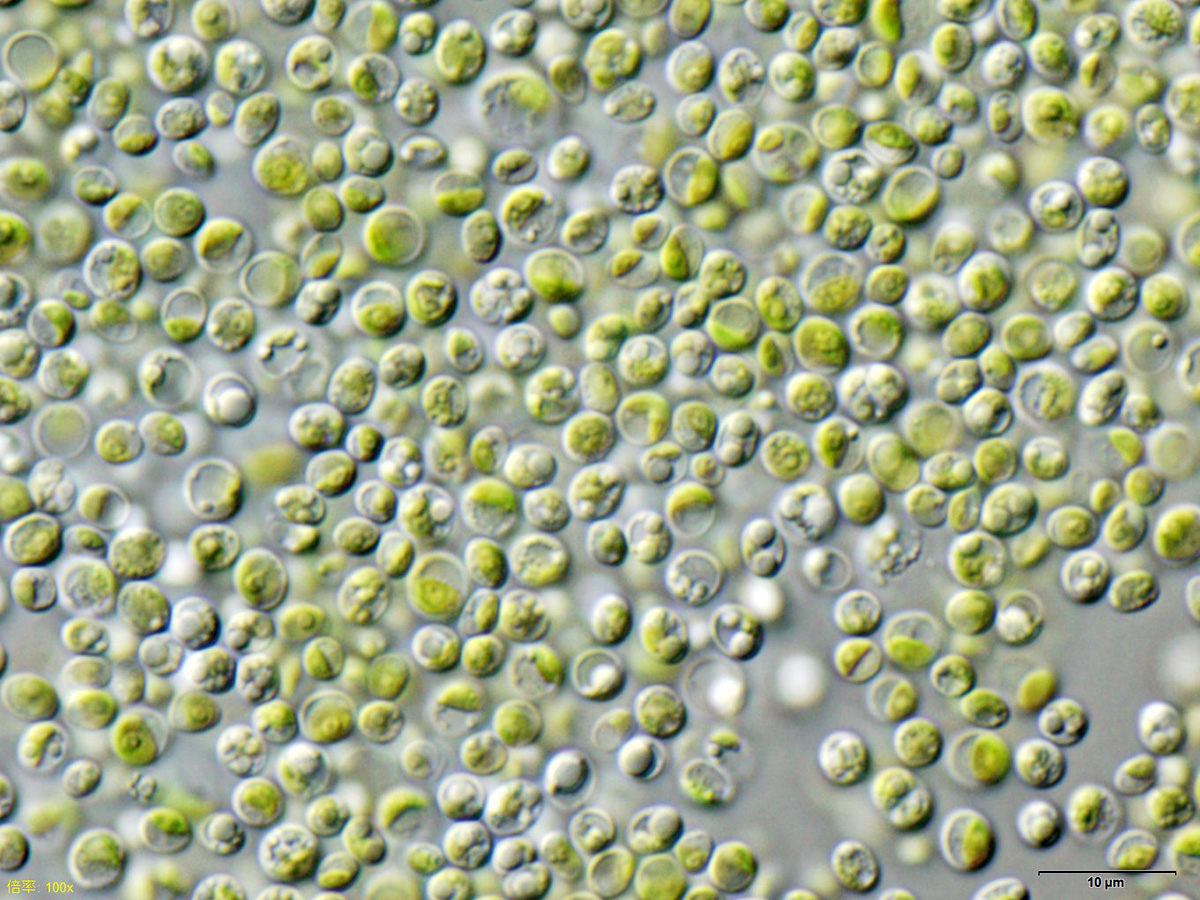

In addition to H2, bacterial photosynthesis also releases CO2, which is fed into a second bioreactor containing green Chlorella vulgaris microalgae. This bioreactor is connected to the first bioreactor. The microalgae bind the CO2 by photosynthesis and incorporate the carbon into their biomass. In addition, they are provided with ammonium chloride (NH4Cl) as a nitrogen source to ensure they grow well and synthesize proteins. Chlorella algae have long been cultivated because they yield large quantities of biomass (of which around 50% consist of protein) for use in industry and agriculture. They are also used to extract special molecules such as lutein, an oxygenated carotenoid (xanthophyll) used as a feed additive and dietary supplement. These unicellular green algae also have the ability to produce H2 from water under certain conditions with the help of sunlight. This can further increase the yield of hydrogen in the SmartBioH2-BW project.

From the laboratory to industrial application

The full title of the project is: "SmartBioH2-BW - Biohydrogen from industrial wastewater and residual streams as a platform for versatile biosynthetic routes". The cooperative project is one of five Urban and Industrial Biorefineries initiative pilot projects launched by the Baden-Württemberg State Agency for Environmental Technology and Resource Efficiency within the framework of the "Bioeconomy - Biorefineries for the recovery of raw materials from waste and wastewater – Bio-Ab-Cycling" ERDF funding programme.

SmartBioH2-BW not only intelligently links the capabilities of purple bacteria and microalgae studied in the laboratory for the climate-neutral biosynthesis of hydrogen and special organic molecules, but also tests this approach in terms of efficiency and cost-effectiveness in an industrial environment. To this end, Evonik Industries, a global leader in speciality chemicals, was recruited as an associated partner for the project, and the biorefinery with the coupled bioreactors for purple bacteria and microalgae was integrated into Evonik Operations GmbH’s large industrial site in Rheinfelden. There, the purple bacteria are fed with wastewater and residual material streams from industrial processes. Evonik has already been producing "grey hydrogen" from natural gas for many decades at the Rheinfelden site, which is used, for example, to produce hydrogen peroxide for the space and food industries.2) If the SmartBioH2-BW pilot project funded by the European Union and the Baden-Württemberg Ministry of the Environment, Climate Protection and Energy Sector is successful, it will be possible to replace at least part of this "grey hydrogen" with "green biohydrogen" in the future.

Info box: SmartBioH2-BW project partners

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart (coordination)

- Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Stuttgart

- University of Stuttgart, Institute of Biomaterials and Biomolecular Systems IBBS

- University of Stuttgart, Institute for Energy Efficiency in Production EEP

- Evonik Industries AG, Rheinfelden (associated partner)

References:

1) Hydrogen production. https://en.wikipedia.org/wiki/Hydrogen_production

2) "H2 Chemistry 2050": Evonik and the Pforzheim University of Applied Sciences are exploring ways for green hydrogen (PR in German). https://corporate.evonik.com/de/presse/pressemitteilungen/standorte/standort-rheinfelden/evonik-und-die-hochschule-pforzheim-erkunden-wege-fuer-grunen-wasserstoff-173004.html