-

Alternative construction materials: mycelium-based materials - 20/12/2023

Most of us see fungi as just food - and possibly pathogens. This is a mistake, because these amazing organisms are capable of much more: they grow on plant residues of all kinds, forming a dense and interconnected structure as they spread. The resulting material can be moulded into desired shapes and be turned into new sustainable and economically attractive products such as leather and polystyrene substitutes or building materials.

https://www.biooekonomie-bw.de/en/articles/news/using-fungi-create-sustainable-and-economical-mycelium-based-materials

-

Sustainable binder alternative - 18/12/2023

Plastic is all around us; and unfortunately, it is not going away any time soon. The search for more sustainable solutions is fully underway. However, binders that degrade only with difficulty or not at all are still used to bond natural materials such as wood and straw - not yet truly environmentally friendly. Fraunhofer researchers are working on an insect-inspired wood binder that makes bonded wood products both resistant and biodegradable.

https://www.biooekonomie-bw.de/en/articles/news/copied-insects-new-biological-wood-binder-under-development

-

The AlbLavendel project - 20/11/2023

Blue-violet, fragrant fields like those in Provence may soon become a common sight in the Swabian Alb. As part of the AlbLavendel project, the University of Hohenheim along with the company naturamus GmbH and the German Institutes of Textile and Fibre Research Denkendorf has started to investigate the cultivation of lavender, the production of essential oils and the use of distillation residues for producing textile fibres in the local region.

https://www.biooekonomie-bw.de/en/articles/news/swabian-lavender-cultivation-aesthetic-and-sustainable

-

Wasser 3.0: #detect|remove|reuse - 31/10/2023

We all pollute our water with things we use in our everyday lives. In the process, microplastics and micropollutants accumulate in sometimes significant quantities and are difficult to remove. This has increasingly devastating consequences for our health and the environment. Wasser 3.0, a non-profit start-up from Karlsruhe, has declared war on this problem by developing a customisable process to detect, remove and even recycle these pollutants.

https://www.biooekonomie-bw.de/en/articles/news/how-sustainably-remove-and-recycle-microplastics-water

-

Innovative materials - 14/06/2023

Conserving wood by producing furniture and other objects from wood-based materials with the help of microorganisms? That is exactly what a team of researchers from the University of Freiburg and the Leibniz Institute for New Materials (INM) in Saarbrücken is working on in the DELIVER project. The aim is to create a database of materials with a broad range of controllable properties for various applications that can be produced from wood waste.

https://www.biooekonomie-bw.de/en/articles/news/reinventing-wood-programmable-bacteria

-

-

3D-Thermocell project - 17/05/2023

Replacing plastic – for example in packaging – is not that easy but nevertheless urgently needed. In the 3D-Thermocell project, researchers at DHBW Karlsruhe are currently developing new plastic substitute products made of thermoformable paper as a renewable resource, which should be cheap and light and easy to dispose of along with waste paper. The characterisation and application of demonstration models will start soon.

https://www.biooekonomie-bw.de/en/articles/paper-instead-plastic-sustainable-packaging-good-conscience

-

Press release - 26/04/2023

Ready-made meals are ideal for quickly satisfying hunger. However, the quick snacks produce a lot of environmentally harmful plastic waste. To tackle this problem, the student team EDGGY from the University of Hohenheim in Stuttgart rolled up its sleeves and developed edible packaging made from eggshells and other plant-based raw materials. And even better: they simply dissolve in the hot water and can be eaten as an additional protein boost.

https://www.biooekonomie-bw.de/en/articles/pm/Simply-EGG-genious-Students-invent-edible-packaging-from-eggshells

-

Residual materials with potential - 16/03/2023

The objective of the PeePower™ BUGA 2023 collaborative research project is to produce green hydrogen and platform chemicals from wastewater. This fits in nicely with BUGA 2023’s (German National Garden Show) four major themes, namely, climate, energy, environment and food security.

https://www.biooekonomie-bw.de/en/articles/pm/peepower-energy-urine

-

-

-

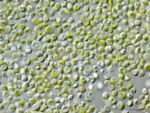

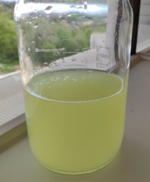

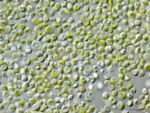

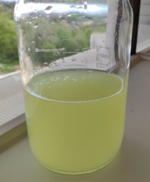

Synergistic effects with microalgae and purple bacteria - 03/02/2023

A biorefinery that uses industrial wastewater and residual material streams is being built in Rheinfelden (Baden). It will have two interlinking bioreactors and will synthesize biohydrogen as well as organic basic materials such as carotenoids and proteins. SmartBioH2-BW is a pilot project run by the Urban and Industrial Biorefineries initiative and funded by the Baden-Württemberg Ministry of the Environment, Climate Protection and Energy Sector.

https://www.biooekonomie-bw.de/en/articles/news/working-towards-hydrogen-economy-wastewater-biorefinery-smartbioh2-bw-project

-

-

-

-

Sustainable nutrition - 05/09/2022

Insects on the dinner plate? Some people instantly dismiss the idea. Wrongly so, because in terms of animal welfare, ecological footprint and healthy nutrition, insect foods are much better than all other animal foods and are produced in a more controlled way. The fact that they can also taste really good is proven by the start-up Beneto Foods from Albstadt, which has developed protein-rich pasta in various flavours using cricket flour.

https://www.biooekonomie-bw.de/en/articles/news/insect-pasta-eating-healthily-and-improving-world-same-time

-

-

Lentil cleaning - EIP-AGRI Rhizo-Linse project - 26/04/2022

The Altdorf mill, just under 7 km south of the city of Böblingen, has operated lentil cleaning facilities since 2019, the year that the Sessler mill in Renningen, 20 km further north, ceased all operations including lentil cleaning. After receiving a number of enquiries from farmers and local mills, brothers Karl and Jörg Ruthardt took a chance and launched a lentil cleaning operation in addition to their mill and farm shop business.

https://www.biooekonomie-bw.de/en/articles/news/lentil-cleaning-altdorf-mill

-

pre-start-up company Wheyfinery - 13/04/2022

There is not much you can do with acid whey, which is why several million litres of it are disposed of every year. This is both costly and not sustainable. However, researchers at Tübingen University have shown: acid whey can be used to produce precursors for biofuels, fine chemicals and antimicrobial livestock feed additives. They have set up the pre-start-up company Wheyfinery in an endeavour to make their scalable biorefinery concept…

https://www.biooekonomie-bw.de/en/articles/news/acid-whey-valuable-raw-material-platform-chemicals-and-more

-

-

-

Further utilisation of plant residues - 25/11/2021

Biogas plants produce energy-rich gas by fermenting biomass. This process generates both liquid and solid fibrous and particulate fermentation residues. Researchers at the German Institutes of Textile and Fibre Research (DITF) have now managed to create a resistant and water-repellent fibre composite material from solid hop residues that can be used as a veneer to coat wood panels.

https://www.biooekonomie-bw.de/en/articles/news/novel-fibre-composite-made-hop-fermentation-residues

-

-

-

Start-up PROSERVATION - sustainable packaging - 21/09/2021

Expanded polystyrene (EPS) packaging is very practical, but it is made from petroleum and is not very environmentally friendly in other ways either. Single-use plastic containers made of EPS have therefore been banned in the EU, but alternatives are also urgently needed. The Stuttgart-based start-up PROSERVATION has developed an ecological packaging material made from grain husks that could replace EPS and be just as effective.

https://www.biooekonomie-bw.de/en/articles/news/husk-substitute-polystyrene-packaging-materials-good-conscience

Website address: https://www.biooekonomie-bw.de/en/search