Main navigation

From cultivation to market – lentils from the Swabian Alb

Complicated cultivation, fluctuating yields and complex cleaning: Leisa – as lentils are called in Swabian – are demanding. So to produce lentils economically, 130 farmers in the Swabian Alb have joined forces and set up the organic producers’ association Alb-Leisa. Their lentil harvests are processed and marketed by a company called Lauteracher Alb-Feld-Früchte.

Lentils are herbaceous plants that can grow up to 50 cm high, depending on the variety. When grown on their own, lentil plants have difficulty remaining upright, and tend to bend over, especially in heavy rain. This makes harvesting difficult and increases the risk of fungal diseases. Therefore, lentils are usually grown alongside so-called companion crops to support them. For the Alb-Leisa farmers in the Swabian Alb (also known as Swabian Jura), oats, malting barley and linseed dodder have proven to be suitable companion crops for the lentil varieties they grow. Two farmers from the Leisa-Alb producers’ association have also participated in the Rhizo-Linse project field trials to help find ways to boost lentil cultivation. The project’s aim is to improve the nitrogen supply to lentil plants in a natural way and to identify the bioeconomic potential of lentil cultivation.

It all started on Mammel, an organic, Bioland-certified farm in Lauterach that has been growing lentils since 1985, initially on just a few hectares. Demand grew and grew, so more farmers started cultivating lentils. The producers’ association Alb-Leisa was founded in 2001 and now comprises 130 farmers who cultivate lentils on a total of 400 to 450 hectares. They all belong to an organic food association and obtain their lentil and companion crop seeds from a company called Lauteracher Alb-Feld-Früchte. The latter, which is also Bioland-certified (Bioland is the largest organic food association in Germany), emerged from the Mammel organic farm that was acquired by Lutz Mammel in 2009, at the time under a different name. Mammel works with twelve employees who receive, process, package and market lentil harvests. Besides lentils, the company’s key own products are buckwheat, linseed dodder oil, pasta, linseed, hemp grains and naked barley. Every year, around 1,000 customers visit the farm shop, and over 8,000 parcels are shipped via its online shop. In addition, the company supplies 1,300 retailers, 100 zero-waste shops and 450 catering establishments.

A field requires a six-year lentil break

"The members of the organic producers' association are linked to Lauteracher Alb-Feld-Früchte through cultivation contracts," explains Franz Häußler, who looks after lentil farmers within the company. These are one-year contracts that specify how many hectares of lentils are sown per crop year and which lentil variety is grown with which companion crop. The contracts also specifiy what was cultivated on the field in previous years. "There must be at least a six-year break from lentil cultivation, otherwise crop rotation diseases will reduce the yield or even cause it to fail altogether," Häußler explains. "Lentils are tricky," he says.

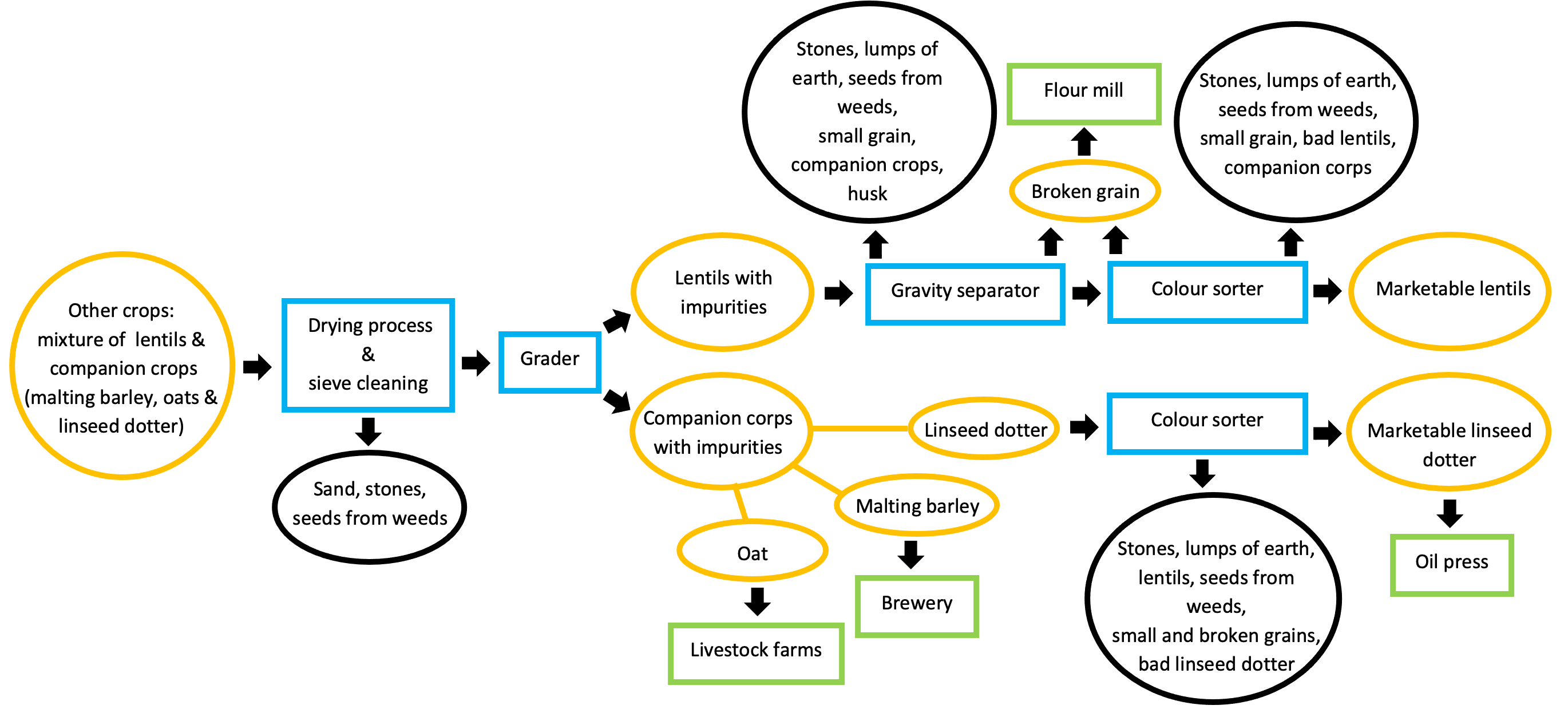

The producers’ association grows three lentil varieties: Späth’s Alblinse I "Die Große" (the big one), Späth’s Alblinse II "Die Kleine" (the small one) and dark green marbled lentils. They can all be planted together with linseed dodder and oats; the dark green variety can also be grown with malting barley as a companion crop. The harvest is collected by Lauteracher Alb-Feld-Früchte on the southern Alb and two farmers on the western and central Alb. The lentils and companion crops are dried on site at a maximum temperature of 40 °C until the lentils’ moisture content is 13 percent. During the drying process, the crop is repeatedly mixed and pre-cleaned with sieves to remove sand, stones and seeds from weeds. Dried in this way, the crop can be stored for several weeks. All further cleaning steps are carried out in the village of Lauterach.

Grader separates round particles from elongated ones

In Lauterach, the lentils and the companion crops are placed in a grader. This separates the round lentils from the elongated companion crops. "The more different the round and elongated parts are, the better the separation works," says Häußler. The grader consists of a sheet metal drum with depressions inside into which the round lentil grains fit perfectly. The elongated companion crop does not fully fit due to its shape. When the drum rotates, the two types of grains remain in the depressions for different lengths of time before they fall out and are collected in different places. As a result of this cleaning step, lentils and companion crops always contain impurities.

In the next step, a gravity separator separates heavy from light. The separator consists of an inclined deck through which low-pressure air is blown upward. Lentils and impurities float in the air flow and arrange themselves according to weight: heavy particles sink to the bottom, lighter particles are lifted to the top. Since the deck is simultaneously vibrating, the heavy particles float uphill and the light ones travel downhill above the heavy particles. The vibrating plate has various discharge spouts and separates lentils, small and broken grains, seeds from weeds, stones, lumps of earth and husks.

Colour sorter blows out unwanted grains

In the final cleaning step, the lentils are put through a so-called colour sorter. Lauteracher Alb-Feld-Früchte has had one for about four years. A computer is used to set the unwanted grain colour that has to be rejected. The lentils and anything else that comes with the harvest are separated on a slide. As the lentils and unwanted grains fall off the end of the slide, they are analysed by cameras, and unwanted grains are blown out at lightning speed. In this way, bad lentils, stones, lumps of earth, seeds from weeds, small and broken grains can be rejected.

The colour sorter can clean a tonne of lentils per hour. There is a limiting factor here as far as the lentil-companion crop combination is concerned: Späth’s Alblinse I and II lentils are more difficult to separate from malting barley in the colour sorter because they are too similar in colour. How often individual cleaning steps have to be repeated depends on the quality of the harvest. "2021 was a very wet year. So we only harvested around 100 tonnes of lentils, which is less than half the usual yield. But we had considerably more work to do,” Häußler says.

"If we were to build the lentil cleaning facility from scratch today, one million euros would not be enough," he says. But it was built little by little, with a lot of tinkering and optimisation. The lentil cleaning system is housed in the old buildings of the organic farm, and the packaging is done in a new building. Sieve separators and graders were already available, but gravity separators and colour sorters were major investments purchased especially for cleaning the lentils. However, they are machines that can be modified to process other crops.

Packaging is a mixture of high-tech and manual work

The lentils are packaged directly after cleaning. "It's a mixture of high-tech and manual work," explains Häußler. In a multihead weigher, cellophane bags are filled with lentils and automatically sealed. The 500 g bags are pushed by hand into folding boxes and packed into cartons 24 at a time. The companion crops follow different routes: the malting barley is usually delivered to an organic brewery directly after having been separated from the lentils. Broken lentils are ground into flour and sold or further processed into pasta. Linseed dodder is cleaned in the colour sorter and then pressed into oil. Oats and other grains that do not meet quality standards go as feed grain to livestock farms within the producers’ association.

As far as the future of lentil growing is concerned, Häußler envisages no problem at all with selling them. But what he does see as major barriers are the long cultivation periods and the lentil processing. The lentil farmers have to be prepared to take risks and see it as a long-term project. There is a lot of solidarity among lentil farmers on the Swabian Alb. Small and part-time farmers are also welcome to join the larger and better equipped farms. "This is smallholder conservation," Häußler says, clearly pleased with how things are working. "Farmers are increasingly becoming lone wolves. That's where the organic producers’association comes in as the antithesis to this, and that's what I find so inspiring about it."

The project will run from March 2019 to early 2022 under the European Agricultural Productivity and Sustainability Innovation Partnership (EIP-AGRI). It will be given a total of €655,500 from the European Agricultural Fund for Rural Development (EAFRD) and the Baden-Württemberg Ministry of Rural Affairs, Food and Consumer Protection.